6S CubeSat Project

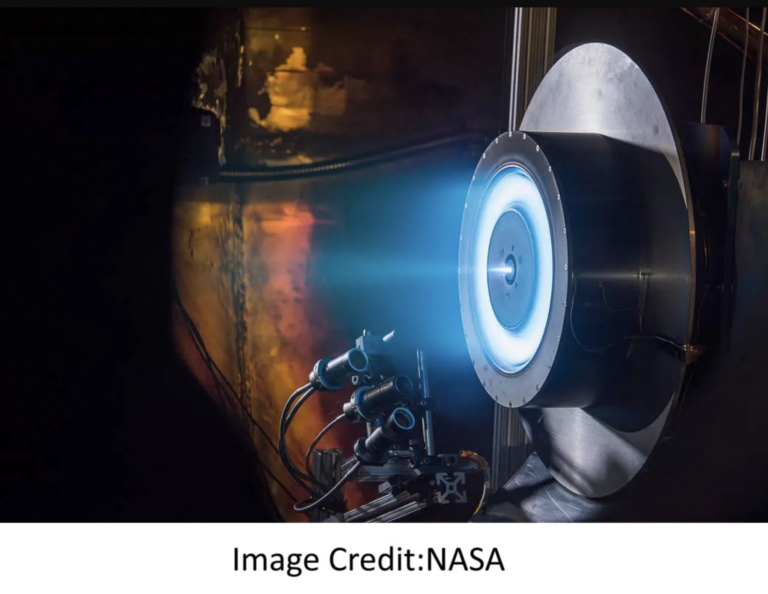

Designing a CubeSat has always been one of the main focus of the association. After creating a team of BSc PoliMi students, the project of the PoliS pace CubeSat started getting shape.

Thanks to a partnership with Sidereus Space Dynamics, the PoliSpace Cubesat will actually take flight towards real space in the early months of 2023.